-

Vineyard Post Roll Forming Machine is fully automatic computer control, automatic production, computer imported from Germany Siemens controller, accurate length measurement, large screen touch screen, easy to operate, the control system can be set in different countries language, can input a variety of production data at a time, the Vineyard Post Roll Forming Machine is automatically produced in sequence, to bring you convenience at the same time. Vineyard Post Roll Forming Machine is mainly used in the fence production. The Vineyard Post Roll Forming Machine processed sheet metal is connected with a series of keels to form small fences such as gardens, villas and courtyards.

-

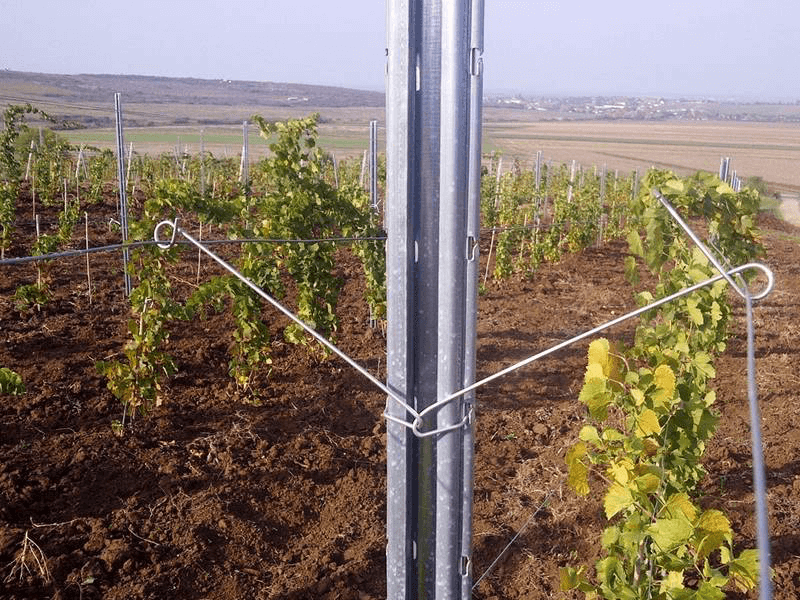

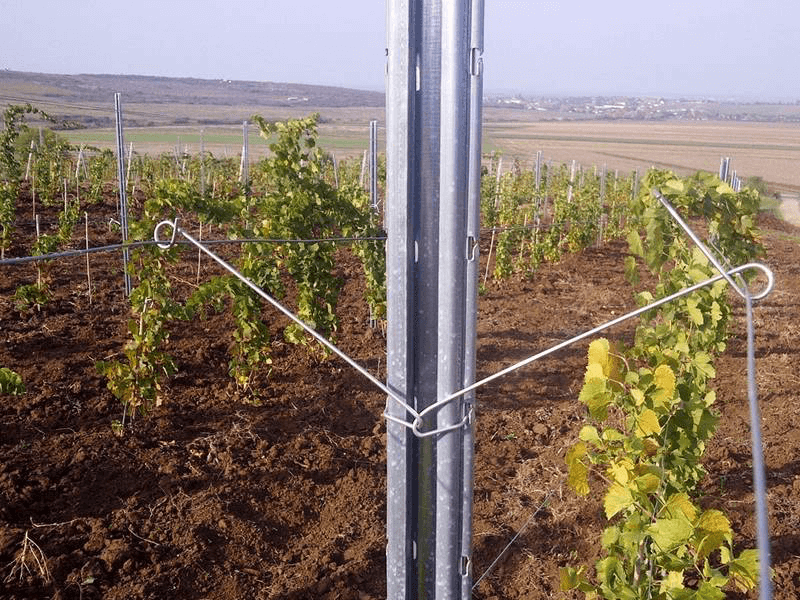

Vineyard posts, or vineyard poles as they are known locally are poles used in the growing of grapes used in the production of wine.Vineyard posts are generally made by galvanized steel , as it is the most cost effective commercially popular all over the world.

-

Working Flow: Decoiler -- Roll-forming -- Presser&cutter -- Output table

description1

Zipper closure

1/4 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them in

place during workout

Product Descriptions

Version to design

Product Parameters

Components:

The major components of the Vineyard Post Roll Forming Machine are listed below:

- Automatic de-coiler

- Feeing guiding device

- Leveling device

- Punching device

- Roll forming machine

- Cutting device

- Computer control box

Technological process:

Uncoiler—Leveling—Feeding—Punching—Roll forming—Hydraulic cutting—Output table

Parameters:

- Raw Material Type: hot rolled steel/GI

- Raw Material Thickness: 1 mm to 3 mm

- Roll Forming Speed: 6-15 m/min

MACHINE INTRODUCTION

Main Components

-

No.

Name

Qty

1

Decoiler

1

2

Main roll forming machine

1

3

PLC Control box

1

4

Hydraulic station

1

5

Output table

2

-

Pictures